Table of Contents

Introduction: The Forever Chemical Reckoning Has Arrived

Imagine discovering that the fire extinguishers protecting your building for decades have been slowly poisoning the environment with chemicals that will outlive your great-great-grandchildren.

Now imagine being told you have less than six months to find, remove, and safely dispose of every single one of them, or face criminal prosecution.

This isn’t a dystopian future – it’s the reality facing every UK business owner on 4 July 2025.

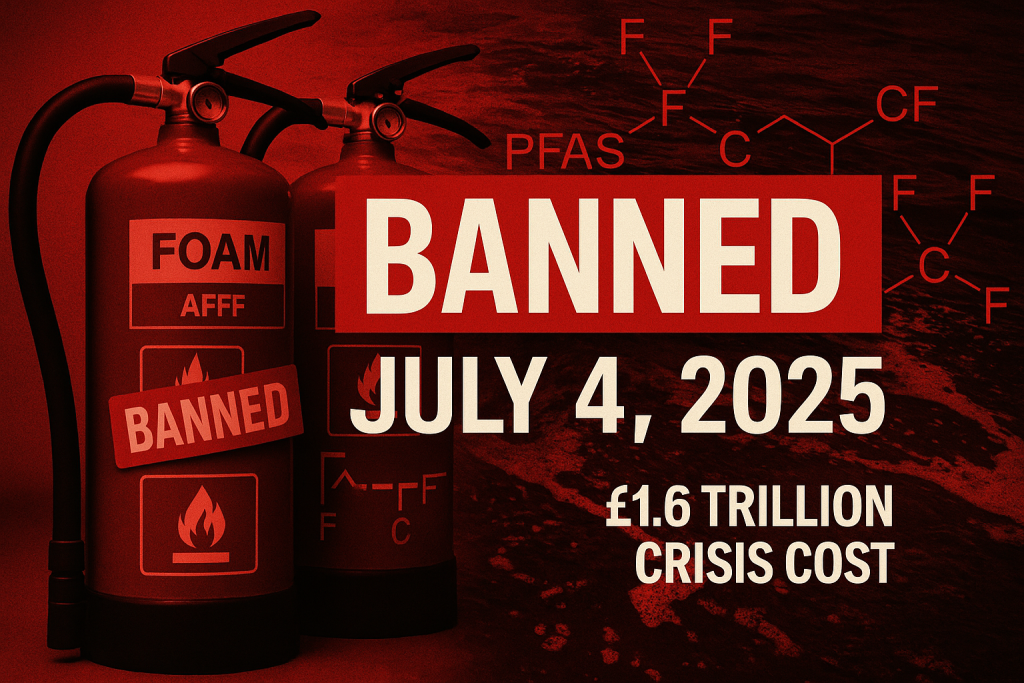

The ban on AFFF (Aqueous Film Forming Foam) fire extinguishers containing PFOA isn’t just another regulatory update to file away and forget. It’s a watershed moment in environmental protection that’s about to trigger one of the most expensive and logistically complex compliance exercises in UK history.

With disposal costs already tripling from £3 to £9 per unit in just one year, only three disposal facilities nationwide struggling to cope with demand, and an estimated environmental cleanup bill of £1.6 trillion across the UK and Europe, this ban represents a perfect storm of regulatory urgency, operational disruption, and financial impact.

The Silent Crisis Nobody’s Talking About

What makes this situation particularly alarming is the silence surrounding it. While the fire safety industry has been sounding alarm bells for months, most UK businesses remain blissfully unaware that their trusted red foam extinguishers are about to become illegal hazardous waste.

There are no official statistics on how many AFFF extinguishers are currently protecting UK businesses – the government doesn’t know, the Environment Agency doesn’t know, and most critically, businesses themselves don’t know.

What we do know is that disposal facilities are already turning away deliveries due to overwhelming demand, and we’re still six months from the deadline.

The chemicals at the heart of this crisis – PFAS, or per- and polyfluoroalkyl substances – have earned the nickname “forever chemicals” for good reason. They don’t break down in the environment, they accumulate in human tissue, and they’re linked to a horrifying list of health impacts including cancer, liver damage, decreased fertility, and increased cholesterol.

Every AFFF extinguisher discharged in training, testing, or emergency response has contributed to a contamination crisis that will take centuries to resolve. The £1.6 trillion cleanup estimate isn’t hyperbole – it’s probably conservative.

This crisis intersects directly with broader fire safety compliance challenges facing UK businesses. Just as building owners are grappling with fire risk assessment legal requirements and the complexities of conducting comprehensive fire risk assessments, they now face the additional burden of completely overhauling their fire suppression systems.

The Regulatory Hammer: What’s Actually Being Banned

The specifics of the AFFF ban are both simpler and more complex than most businesses realize. Starting 4 July 2025, any fire extinguisher containing PFOA (perfluorooctanoic acid) becomes illegal to use, store, or refill in the UK.

This isn’t a phase-out or a restriction – it’s a complete prohibition under the UK REACH and Persistent Organic Pollutants regulations. The Environment Agency, which oversees enforcement, has made it crystal clear that there will be no grace period, no exemptions for small businesses, and no tolerance for non-compliance.

The Confusion Factor

But here’s where confusion begins to spread like, well, foam on a fire. Not all foam extinguishers contain PFAS, and not all PFAS-containing foams are being banned – yet. The July 2025 ban specifically targets PFOA, one particular type of PFAS chemical.

However, this distinction is largely academic for most businesses because identifying which specific PFAS chemicals your extinguishers contain is virtually impossible without manufacturer documentation.

Quick identification guide:

- Before 2016: Almost certainly contains PFOA

- 2016-2020: Might contain other PFAS chemicals

- “Fluorine-free” or “F3” labeled: Safe from current and future bans

The Legal Framework

The regulatory framework driving this ban is a complex web of international agreements and domestic legislation. The Stockholm Convention on Persistent Organic Pollutants, which the UK is party to, requires the elimination of PFOA. The UK REACH regulation provides the enforcement mechanism.

The Environment Agency has been designated as the primary enforcement body, with Trading Standards and the Health and Safety Executive playing supporting roles. This multi-agency approach means businesses can’t slip through the cracks – someone will be checking, and someone will be enforcing.

What many businesses don’t realize is that this ban extends far beyond just the extinguishers themselves. Any system that uses AFFF – from fixed suppression systems in server rooms to mobile foam units in warehouses – falls under the prohibition.

The foam concentrate stored in your fire equipment room, the spare extinguishers in your maintenance shed, even the old units gathering dust in forgotten storage areas – all become illegal hazardous waste on 4 July 2025.

This regulatory complexity mirrors the challenges businesses face with other fire safety compliance requirements. Just as fire safety employees have specific responsibilities that must be clearly understood and documented, the AFFF ban creates new legal obligations that require immediate attention and action.

The Disposal Crisis: A Ticking Time Bomb

The disposal challenge facing UK businesses is nothing short of catastrophic. With only three licensed facilities in the entire UK capable of safely destroying PFAS-contaminated foam, we’re watching a slow-motion disaster unfold.

These facilities use high-temperature incineration – one of the few methods that can actually break down PFAS chemicals – but their capacity is limited, their waiting lists are growing, and their prices are skyrocketing.

The Numbers Don’t Lie

The numbers tell a story of escalating crisis:

- Early 2024: £2-3 per unit disposal cost

- October 2024: £8-9 per unit (nearly tripled)

- July 2025 projection: £15-20 per unit or more

For a medium-sized office building with 50 foam extinguishers, that’s a disposal bill jumping from £150 to potentially £1,000, not including transportation, documentation, and replacement costs.

But the real crisis isn’t the cost – it’s the capacity. Several major waste management companies have already stopped accepting AFFF extinguishers entirely, overwhelmed by the volume they’re receiving. Others are implementing strict quotas, limiting businesses to disposing of 10-20 units at a time.

The Hidden Contamination Problem

What nobody’s talking about is the hidden contamination already present in thousands of UK buildings. Every time an AFFF extinguisher has been tested, discharged, or even slightly leaked over the past decades, it’s left PFAS residue that’s now considered hazardous contamination.

Floors where extinguishers have been stored, drains where foam has been washed, soil where training exercises were conducted – all potentially contaminated sites that may require professional remediation.

A logistics company in Birmingham discovered PFAS contamination in their warehouse floor after an AFFF extinguisher had leaked years earlier. The cleanup cost £85,000 and required the facility to shut down for three weeks.

This disposal crisis adds another layer of complexity to existing fire safety maintenance requirements. Businesses already struggling with fire extinguisher testing schedules and compliance now face the additional burden of hazardous waste management and environmental remediation.

The Alternative Solution Maze: F3 Foam and Beyond

The transition from AFFF to fluorine-free alternatives should be straightforward – out with the old, in with the new. But like everything else about this ban, the reality is far more complex and expensive than anyone anticipated.

The alternatives exist, they work, and in some cases, they’re actually better than AFFF. But getting from where we are to where we need to be is a journey filled with technical challenges, compatibility issues, and costs that nobody budgeted for.

The Success Stories

Fluorine-free foam (F3) has emerged as the primary replacement for AFFF, and the success stories are genuinely impressive. London Heathrow Airport’s experience reads like a best-case scenario – they’ve successfully used F3 foam on two actual aircraft fires, an Airbus A321 and a Boeing 787, with perfect results both times.

The environmental cleanup cost after these incidents? Zero. The foam was simply washed into the drainage system with the Environment Agency’s blessing. Compare that to their 2008 experience with AFFF, which cost thousands of pounds and took months to clean up, and the advantages become clear.

The Reality Check

But Heathrow’s success doesn’t automatically translate to every business. F3 foams have different physical properties than AFFF – they’re often more viscous, they may require different application techniques, and they don’t create the same vapor-sealing film that made AFFF so effective on fuel fires.

For airports with trained firefighters and specialized equipment, these differences are manageable. For a small business with a few foam extinguishers and staff whose fire training consists of a 20-minute video, the transition is far more challenging.

The Training Challenge

Training represents another hidden cost that businesses are only just beginning to understand. F3 foams behave differently than AFFF – they may take longer to knock down flames, they might require different application patterns, and they definitely need different maintenance procedures.

Every member of staff who might use a fire extinguisher needs retraining. Every fire marshal needs updated procedures. Every emergency response plan needs revision.

A large hospital in Manchester calculated that retraining their 3,000 staff members on new F3 foam procedures would cost £180,000 in staff time alone, not including the cost of trainers, materials, and lost productivity during training sessions.

This transition challenge connects directly to broader fire safety planning requirements. Businesses updating their fire suppression systems must also review their fire safety policies and ensure their office fire risk assessments account for the new equipment and procedures.

Sector-Specific Nightmares: When One Size Doesn’t Fit All

The AFFF ban’s impact varies dramatically across different sectors, and some industries are facing challenges that border on insurmountable.

Petrochemical Sector: Energy Security at Risk

The petrochemical sector, in particular, is staring down the barrel of a compliance crisis that could fundamentally affect UK energy security. These facilities don’t just have a few foam extinguishers in corridors – they have massive foam suppression systems protecting tank farms, loading facilities, and process areas where hydrocarbon fires represent existential threats.

A petrochemical facility in Grangemouth recently discovered that switching from AFFF to F3 foam required replacing not just the foam concentrate but the entire proportioning system, new pipework rated for different pressures, modified nozzles, and recalibrated detection systems. The total bill? £2.3 million for a facility that initially budgeted £50,000 for foam replacement.

Offshore Platforms: Extreme Environment Challenges

The oil and gas industry’s predicament is particularly acute offshore. North Sea platforms operate in some of the most challenging fire safety environments imaginable – confined spaces, extreme weather, limited evacuation options, and the constant presence of hydrocarbons.

AFFF has been their gold standard for decades because it works fast, spreads effectively even in high winds, and creates a vapor barrier that prevents re-ignition. F3 foams, while improving rapidly, haven’t yet proven themselves in the extreme conditions of a North Sea winter storm.

Healthcare: Lives on the Line

Healthcare facilities present perhaps the most complex compliance challenge. Hospitals can’t simply shut down for fire system upgrades, they can’t evacuate during system testing, and they can’t risk suppression system failures when lives literally depend on continuous operation.

Many NHS facilities have aging foam systems that haven’t been properly maintained for years due to budget constraints. Now they’re being told these systems aren’t just inadequate – they’re illegal. The NHS faces an estimated £50 million bill just for AFFF replacement, money that could otherwise fund thousands of medical procedures.

These sector-specific challenges highlight the importance of tailored fire safety approaches. Just as different building types require specific fire risk assessment examples and workplace fire hazard assessments, the AFFF transition demands industry-specific solutions and timelines.

The Financial Reality: Counting the True Cost

When businesses first hear about the AFFF ban, they typically budget for the obvious costs – disposal fees and replacement extinguishers. The reality is that these direct costs are just the tip of a very expensive iceberg.

The Visible Costs

Let’s start with the numbers everyone can see:

- Foam extinguisher replacement: £150-300 per unit

- Disposal costs: £9-15 per old unit

- Transportation and documentation: Additional 20-30%

For a medium-sized office building with 20 foam extinguishers, that’s £4,000-8,000 for what seems like a straightforward swap.

The Hidden Costs

But that’s where the simple calculations end and the real costs begin. System compatibility issues can multiply expenses exponentially. The project took eight months to complete, during which time the facility operated with reduced fire protection and increased insurance premiums.

Documentation and compliance costs add another layer of expense that many businesses underestimate. The Environment Agency requires detailed records of AFFF disposal, including chain of custody documentation, waste transfer notes, and certificates of destruction.

Getting these documents wrong can result in prosecution for illegal waste handling. Many businesses are hiring specialist environmental consultants at £150-200 per hour to manage the paperwork, adding thousands to the total cost.

Insurance Implications

Insurance implications are creating additional financial pressure across all sectors. Many insurers are now requiring proof of AFFF compliance before renewing policies. Some are increasing premiums for businesses that haven’t yet transitioned away from AFFF, viewing them as higher environmental liability risks.

A few insurers have started excluding PFAS contamination from new policies entirely, leaving businesses potentially exposed to unlimited cleanup costs.

The opportunity costs may be the most significant of all. Every hour spent dealing with AFFF compliance is an hour not spent on core business activities. A manufacturing company in Leeds calculated that their management team spent 400 hours over six months dealing with AFFF transition planning – time that could have been spent on a new product launch that was delayed as a result.

These financial realities underscore the importance of comprehensive fire safety planning. Businesses need to integrate AFFF compliance costs into their broader fire safety housekeeping practices and ensure their fire safety budgets account for these new regulatory requirements.

The 30-Day Emergency Action Plan: What You Must Do Now

With less than six months until the July 4, 2025 deadline, businesses can’t afford to wait for perfect information or ideal solutions. The disposal capacity crisis means that even businesses ready to comply may find themselves unable to dispose of their AFFF extinguishers if they wait too long.

Days 1-3: Immediate Inventory and Risk Assessment

Your first priority is finding every AFFF extinguisher on your premises. This isn’t as simple as it sounds – foam extinguishers might be in maintenance areas, storage rooms, vehicle bays, or forgotten corners of your facility.

Check manufacturing dates and labels carefully:

- Any extinguisher manufactured before 2016 almost certainly contains PFOA

- Units from 2016-2020 might contain other PFAS chemicals

- Only extinguishers explicitly labeled “fluorine-free” or “F3” are definitely safe

Document everything with photographs and serial numbers. Create a spreadsheet listing location, manufacturer, model, manufacturing date, and last service date for every unit.

Days 4-7: Disposal Facility Research and Booking

Contact all three licensed PFAS disposal facilities in the UK immediately. Don’t wait – their capacity is filling up fast, and some are already turning away new customers. Get quotes in writing and book disposal slots as soon as possible, even if you’re not ready to dispose yet.

Research transportation requirements carefully. AFFF extinguishers are classified as hazardous waste and must be transported by ADR-certified drivers using appropriate vehicles.

Days 8-14: Replacement System Planning

While your disposal arrangements are being finalized, start planning your replacement fire suppression systems. This is where technical expertise becomes essential – don’t try to do this alone.

Engage a qualified fire safety consultant who understands both the regulatory requirements and the technical challenges of transitioning from AFFF to alternatives.

Consider your specific fire risks carefully:

- F3 foam works well for most applications

- Server rooms might benefit from gaseous suppression systems

- Vehicle maintenance areas might need specialized foam formulations

- Kitchen areas might require different approaches entirely

Days 15-21: Staff Training and Procedure Updates

Start updating your fire safety procedures immediately. Your existing emergency response plans probably assume AFFF extinguishers will be available – these plans need revision to account for new equipment and procedures.

Begin staff training on the new systems, even if they’re not installed yet. F3 foams behave differently than AFFF, and your staff need to understand these differences before an emergency occurs.

Days 22-30: Implementation and Documentation

Execute your disposal plan as soon as possible. Don’t wait until the last minute – disposal facilities are already overwhelmed, and delays could leave you with illegal hazardous waste after July 4, 2025.

Install your replacement systems and commission them properly. Test everything thoroughly and document the testing. Update your fire safety certificates and ensure your insurance company is notified of the changes.

Create a compliance file documenting everything you’ve done – disposal certificates, installation records, training records, and updated procedures.

This emergency action plan connects directly to broader fire safety management requirements. Businesses implementing these changes should also review their overall fire risk assessment processes and ensure their fire alarm testing schedules and emergency light testing remain current during the transition.

Looking Beyond July 2025: The Future of Fire Safety

The AFFF ban is just the beginning of a broader transformation in fire safety technology and regulation. Understanding what’s coming next can help businesses make smarter decisions about their fire suppression investments and avoid costly mistakes.

Regulatory Momentum

The regulatory momentum behind the AFFF ban isn’t slowing down – it’s accelerating. The European Union is already planning to ban all PFAS chemicals by 2030, not just PFOA. The UK is likely to follow suit, meaning that any PFAS-containing foam you install today might be banned again in five years.

This regulatory trajectory strongly favors fluorine-free alternatives, making F3 foam the safest long-term investment for most businesses.

Technology Developments

Technology developments are making F3 foams increasingly attractive. New formulations are addressing the performance gaps that initially made some industries reluctant to switch. Improved spreading agents are making F3 foams more effective on hydrocarbon fires.

Better proportioning systems are solving the compatibility issues that plagued early adopters. Some new F3 formulations actually outperform AFFF in specific applications, particularly in cold weather conditions where AFFF traditionally struggled.

Environmental Liability

Environmental liability is becoming a major business risk that extends far beyond fire safety. The £1.6 trillion cleanup cost estimate for PFAS contamination across Europe represents one of the largest environmental liabilities in history.

Businesses that have used AFFF may face future cleanup costs, legal liability, and regulatory action even after they’ve switched to alternatives. Early transition to F3 systems demonstrates environmental responsibility and may provide some protection against future liability claims.

This forward-looking perspective emphasizes the importance of comprehensive fire safety planning. Businesses should integrate AFFF compliance with their broader fire safety strategies, including regular fire risk assessments, proper fire extinguisher testing, and ongoing fire alarm testing programs.

Conclusion: The Choice Between Crisis and Opportunity

The AFFF fire extinguisher ban represents one of the most significant regulatory challenges facing UK businesses in decades. With less than six months until the July 4, 2025 deadline, the window for orderly compliance is rapidly closing.

The disposal capacity crisis, escalating costs, and technical complexity of transitioning to alternatives mean that businesses can’t afford to delay action any longer.

The Opportunity Within the Crisis

But within this crisis lies an opportunity for businesses that act decisively. Early adopters of F3 foam technology are discovering that the alternatives often perform better than AFFF while eliminating environmental liability risks.

Companies that transition quickly are securing disposal capacity at lower costs and avoiding the rush that will inevitably come as the deadline approaches. Most importantly, businesses that demonstrate environmental leadership through early AFFF elimination are positioning themselves advantageously with insurers, regulators, and environmentally conscious customers.

The Strategic Approach

The key to success is treating the AFFF ban not as an isolated compliance exercise but as part of a comprehensive fire safety strategy. Businesses that integrate AFFF compliance with broader fire safety improvements – updating fire risk assessments, improving staff training, modernizing fire suppression systems – will emerge stronger and better protected than before.

The £1.6 trillion environmental cleanup cost represents the price of decades of environmental negligence. The AFFF ban is our opportunity to break that cycle and build fire safety systems that protect both people and the planet.

Your Next Steps

The businesses that seize this opportunity will thrive in the post-AFFF world. Those that don’t may find themselves facing not just regulatory prosecution but environmental liability that could threaten their very existence.

The choice is clear, and the time for action is now. Your business, your employees, and future generations are counting on the decisions you make in the next 30 days.

For comprehensive fire safety support during this transition, including professional fire risk assessments, fire extinguisher testing services, and fire alarm testing, businesses should engage qualified fire safety professionals who understand both the regulatory requirements and the technical challenges of the AFFF transition.